Research and Development

Development concepts

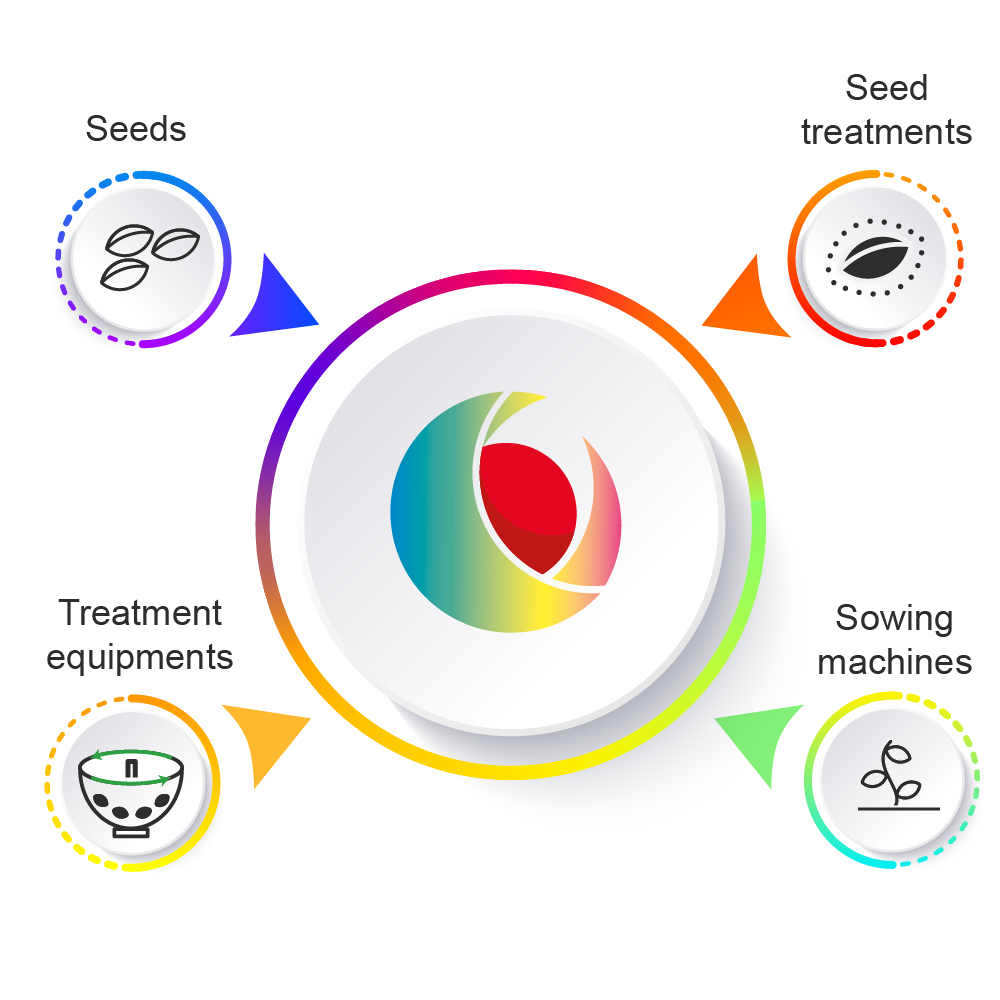

We work in close conjunction with the following adjacent businesses to resolve any technical issues specific to a customer

– Seeds

– Seed treatments

– Treatment equipments

– Sowing machines

The 3S’s

Three fundamental goals guide the development of our products from start to finish:Singulation, Speed et Safety .

Click on the tabs below to discover the 3S.

- Singulation (S1)

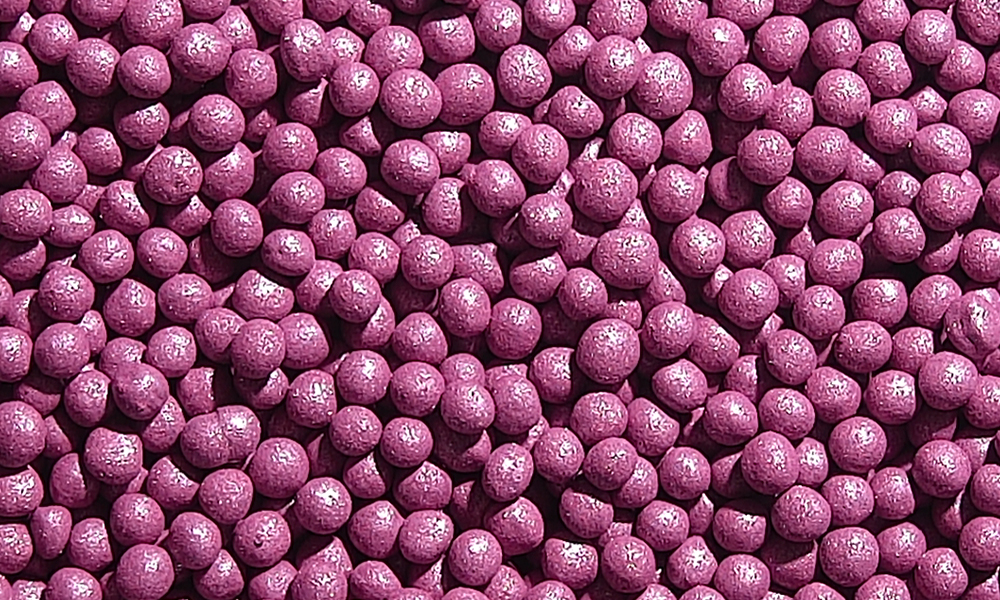

Because every seed counts, it is essential that each seed remain individualized throughout the application process, from drying through bagging, storage, transport and sowing – whatever the species, the lot, the coated product, the processes applied or the processing equipment. The Aegilops Build up Technology (ABT) application process is a good answer to some of the problems encountered on certain seeds that are difficult to sow.

- Speed (S2)

Seed professionals and farmers need to optimize both speed and quality of their operations. Today, machines are increasingly efficient, sophisticated and connected to achieve this goal. We anticipate this evolution and develop different technologies in order to improve the “plantability” of treated seeds.

Increasing the flow of seeds at sowing is highly appreciated by farmers who face strong climatic pressure at this time of the year.

In fact, in many countries the “sowing windows” are particularly narrow. The potential yields are penalized from the start if sowing is not successful

We have developed Aegilops Easyflow Technology (AET) that greatly improves the flow of seeds deemed difficult to sow such as sunflower, thus replacing the powders dispersed by the sowing machine.

- Safety (S3)

We are constantly focused on Health, Safety and Environment (HSE) to limit the impact of our products. Therefore, our objective is to propose products that meets regulatory requirements, easy-to-use, and free of toxicity classification.

For example, AGIFIX 75 C, AGIFIX 75 SB and AGIFIX 150 SF were developed to reduce the well-known negative effects of pyrethroid insecticides applied on seeds

Moreover, to comply with forthcoming new microplastic legislation, we are developing a new generation of microplastic-free products which will soon be available for certain crops.

HSE initiatives are part of a “Stewardship” program ensuring the safe and sustainable use of our products.

Execution of the 3S’s through adjacent businesses

We develop our solutions through a network of experts in adjacent businesses.

Seeds

We work closely with our seed and grower partners to

- Develop processes and products adapted to their seeds

- Respond to technical application problems (selectivity, fluency, dust off level, etc.)

- Meet regulatory standards

- Optimize the treatment capacity at seed plants

Seed treatments

Our objective is to optimize application recipes in order to use the right dose of protection products, in the right place and at the right time.

We are in close contact with the suppliers of treatment products that are based on conventional or natural chemistry to ensure the effectiveness of partner products used in recipes.

Problems such as dust, flow and stability are essential points taken into account in the products design.

Treatment equipments

The characteristics of our products and processes are established in cooperation with treating equipment manufacturers.

Sowing machines

We have close ties with sowing machine manufacturers to conduct tests with our products in order to assess the plantability of the treated seeds. Seed unit fouling is assessed under different conditions to ensure the robustness of the different recipes recommended.

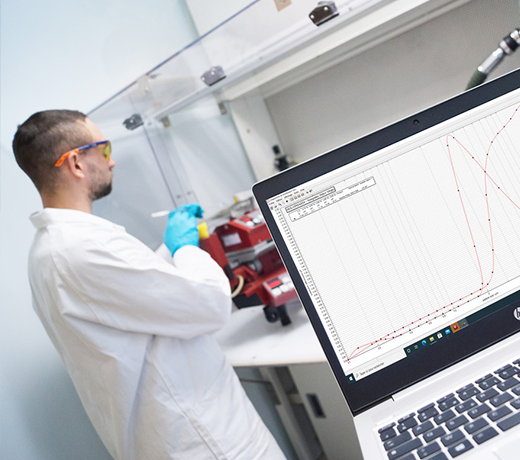

Our new Development Center

Our new Development Center: A step towards a new generation of product!

Our R&D laboratory is in Pharma Parc in Val de Reuil, which brings together numerous start-ups working on “new tech” in chemicals and pharmaceuticals. This is bringing privileged access to chemical experts and cutting-edge lab equipment. This development center enables us to seek innovative solutions to meet future market needs.

3 main activities

To develop our new products, we undertake 3 main activities: Formulation, Application and Analysis, described below with one click.

Click on the tabs below to discover our activities

- FORMULATION

A molecular approach

We use high performance, molecular analysis to develop new formulas. When developing a new formula, we first specify the molecular composition of all the materials proposed. Next, we use high performance devices such as laser particle size analyzers and electron microscopes to test, analyze and validate that the product composition meets specifications. For example, analyzing the particle size distribution was a key step in developing Agipowder 773.

An innovative formulation

We study the physicochemical characteristics of each formulation to improve flow, coverage and dust-off control on the seed. We use equipment and tools such as viscometers, LENETA tests, fluidized air beds, and high dispersion mixers. These cutting-edge technologies help us efficiently develop the products of tomorrow that are both sustainable and free of microplastics.

Click on the opposite tab Application to discover this activity

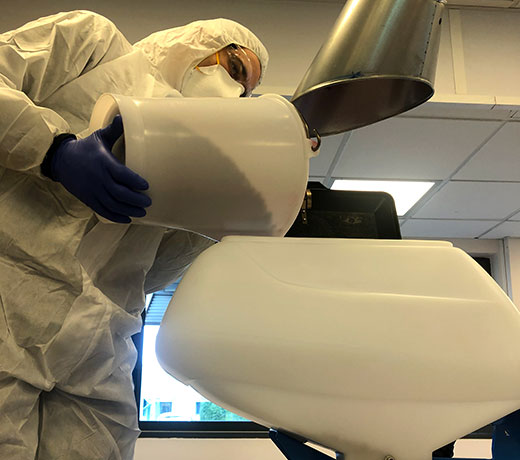

- APPLICATION

A new generation of substances

Our new formulations make it possible to optimize the seed treatment capacities in industrial facilities. To do so, our labs have the equipment to carry out pilot manufacturing and semi-industrial applications, allowing us to simulate the product’s industrial use.

Seeding optimization

We test our products on diverse sowing machines to evaluate the plantability of the treated seeds treated. Aegilops’ EasyFlow Technology (AET) is designed to improve the fluency of the treated seeds and deliver superior sowing quality at a higher speed.

Click on the opposite tab Analysis to discover this activity

- Analysis

Monitored selectivity

We study the impact of recipes containing our products on the germination of seeds in ISO 6 and ISO 7 germination rooms, equipped with temperature, relative humidity and light controls. By using rigorous analysis, we ensure that our solutions have no negative effect on germination.

The search for the robust “slurry - seed” pair

We use chromatography to test the loading of the active substances applied to seeds. Thus, some products such as Agifix 75C have been designed to greatly reduce dust-off on treated seeds and to better fix the active ingredients in the film coating placed on the seed.

Click on the opposite tabs to discover our activities.

Standards

We have adopted high standards across our various activities, which allows us to:

– Guarantee the performance of our products

– Guarantee the quality of results

– Compare these results on common grounds between businesses and countries

– Properly meet regulatory constraints

Our products have high quality and safety standards, which are made possible by our technical expertise.

Our main tests

Here are the main tests that we perform in our laboratories to validate a product or an application recipe, including when our product is applied with other products:

Click on the tabs below to discover the test

Physico-chemical compatibility tests

These tests, carried out in the laboratory, have three objectives:

– Miscibility between the different constituents of the recipe

– Stability over time under different temperatures

– The absence of negative interaction with the active substances of the treatments

– The absence of toxicity of the mixtures

Heubach Test

ESTA (European Seed Treatment Assurance) reference, methods and protocols

This test is carried out on treated seeds and has the following objectives:

– To measure the amount of volatile dust in a treated seed

– To keep its quantity below the limits officially established per crop

– To manage the environmental risk through limited emissions into the air

– To enhance indirectly the farmer safety while handling the treated seeds

Drill-plantability and flow tests

These trials are carried out on seeds as pilot tests in our laboratory during the development of our formulations and application recipes. They are practiced at two levels:

– In the laboratory, after application of the products, drying and storage studies of the treated seeds

– In the field to ensure flow in several sowing machines under different conditions.

Deposit on machines

These tests inform us about the resistance to abrasion of the film coating applied to seeds.We simulate the real deposit phenomena in the treater or in the planter machines.

Seed coverage tests

In this test, we study the uniformity of the product distribution onto the seed.

Agronomic tests

All our products and application recipes are subject to germination tests in the laboratory and in the field to verify their selectivity on the seed and the absence of negative effects on the growth of the seedling.